Filtrox

REGIONAL: ME, VT, NH, MA, NY, NJ, PA, RI, CT, MD, DE, OH, WV, KY, IN, IL, WI, MI, MN, ND, SD

Oil Filtration Management

Challenges

Solution

We operate on the premise that we are a solution provider for our customer’s frying oil filtration needs. Your long-term satisfaction is our goal. You’ll have the results to prove it: cleaner oil, longer lasting, less usage, greater savings – plus consistent quality food.

Key Products

LS-2 Unit

Portable Filtration Machine

The LS-2 Unit simplifies filter changes with the use of SuperSorb Pads, making powder unnecessary. While having a smaller footprint, the LS-2 Unit offers a larger volume, providing 20% more capacity than competitive units.

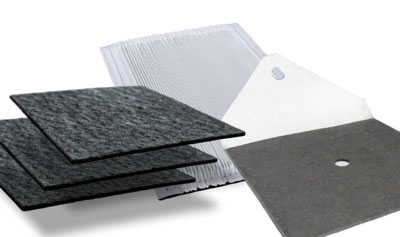

SuperSorb® Carbon Pads

Portable Filtration Machine

3 different types of SuperSorb® Carbon Pads in different sizes are available, designed for most common deep fryers on the market.

The increased depth of the Carbon Pads allows multiple stages of filtration.

1. Larger solids are held on the surface of the pad.

2. Smaller solids are trapped within the structure. The structure has a very high volume of internal pores so can hold a high degree of solids.

3. The internal structure gets tighter the further you travel through the pad ensuring even the finest solids are trapped.